Passive:First Steps: Unterschied zwischen den Versionen

SebSta (Diskussion | Beiträge) |

SebSta (Diskussion | Beiträge) |

||

| Zeile 208: | Zeile 208: | ||

== Step Ten: Intermezzo with the unheated attic == | == Step Ten: Intermezzo with the unheated attic == | ||

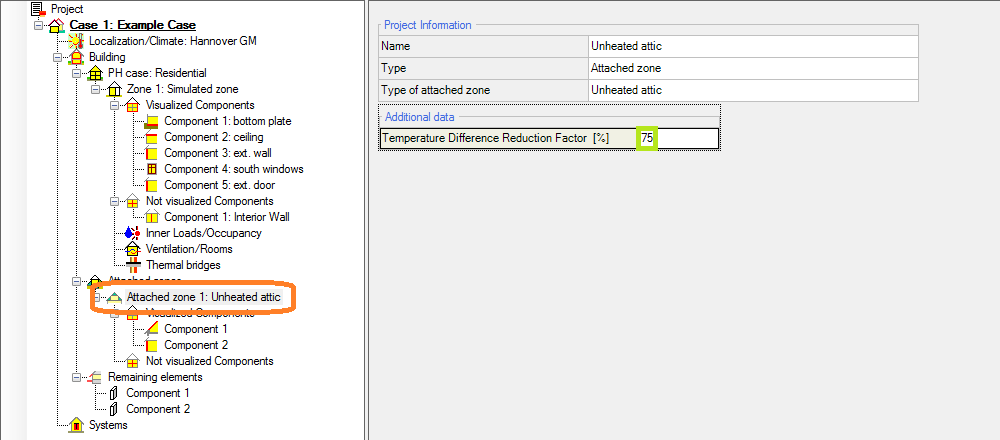

For simplicity of this example, the attic is unheated and unventilated but does have a temperature difference reduction factor of 75%. | |||

[[Bild:Passive-example_unheated_attic.png|center|Chaning the heat reduction factor of the unheated attic]] | [[Bild:Passive-example_unheated_attic.png|center|Chaning the heat reduction factor of the unheated attic]] | ||

== Step Eleven: Adding the HVAC systems == | == Step Eleven: Adding the HVAC systems == | ||

Version vom 16. Juli 2013, 13:31 Uhr

Example Case

This example will give you an easy step by step guide, on how to input a new case in WUFI®Passive. It will be a very easy case and is inspired by the introduction movie. For more advanced stuff, go to the advanced example.

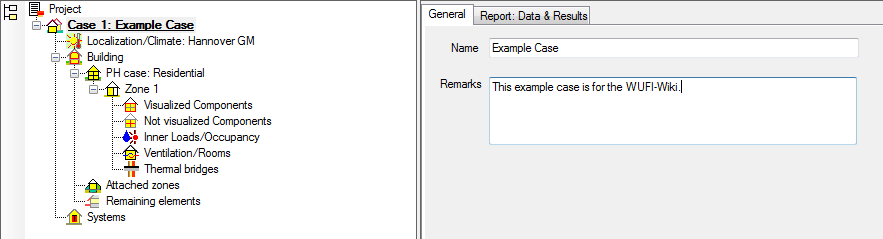

Step Zero: Case 1

In contrast to WUFI®Plus, this section does not contain any essential data but you can name your project and add some remarks.

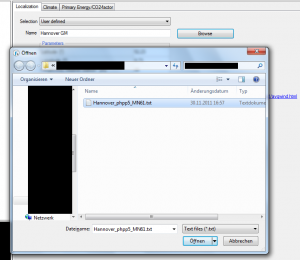

Step One: Climate and Localization

WUFI Passive's standart climate is the german reference climate as in DIN 4108-6 but we will use a different climate, in our case it will be from Hannover. To input a new climate dataset select the "user defined" scope and press the browse button. After you input some valid data, the climate tab will show some graphs about temperature and radiation.

Remember that WUFI®Passive needs a special format of climate files which you can see it in the previous link or in this movie.

If you dont have any climate files formated this way, you can switch to WUFI®Plus and input the climate file there. Detailed instructions can be found here.

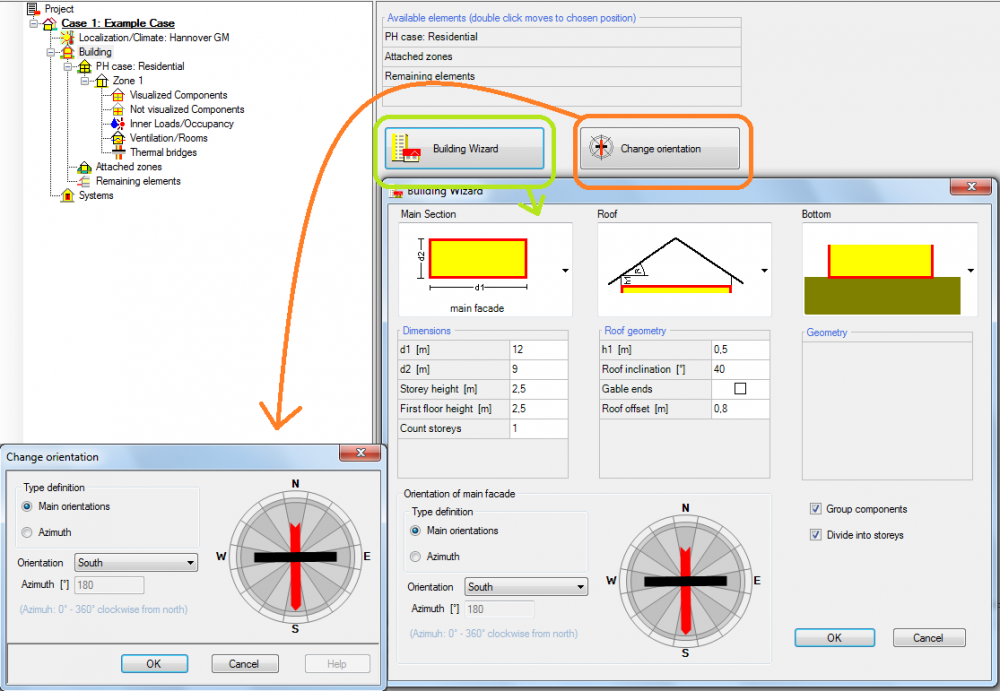

Step Two: Building geometry

There are 3 ways to define a building in WUFI®Passive, the easiest one being the building wizard for very simple buildings or spaces. The two other ways are verticles and Sketchup, which work way better if you want to build a more complex building.

For our example we will use a simple room with an unheated attic and a slab on grade zone.

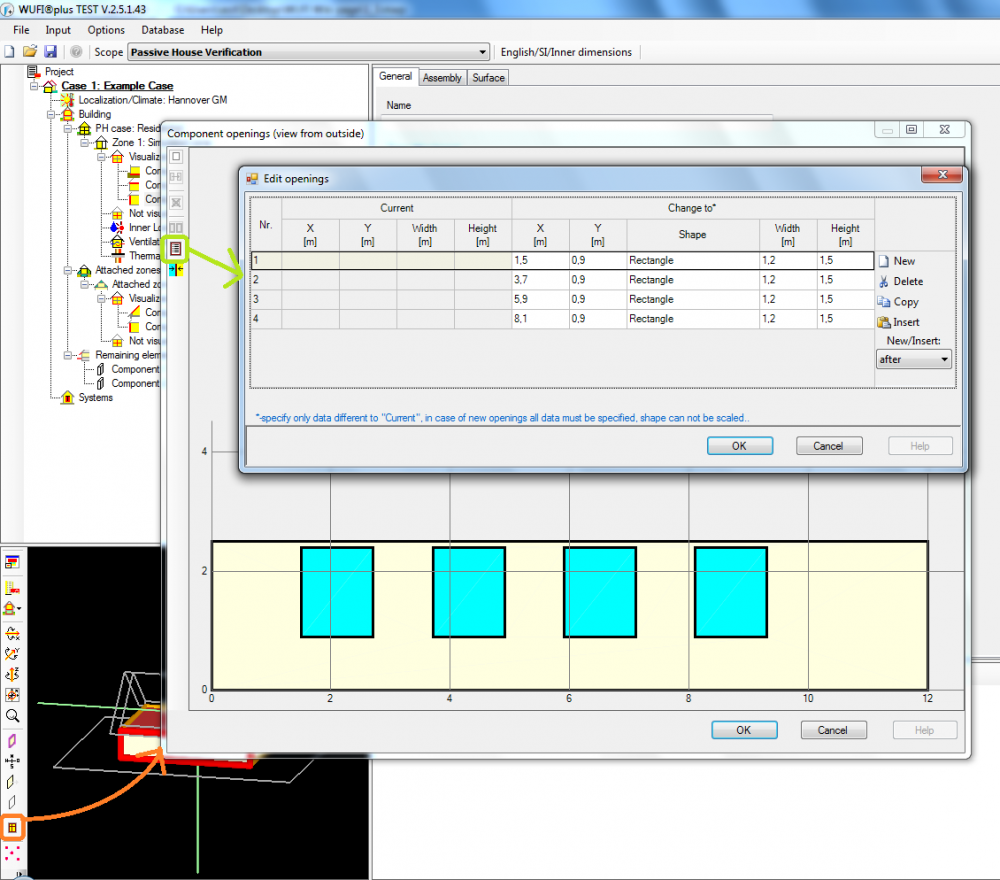

We will add 4 windows on the south side using the visualization box in the bottom left corner. Click the orange boxed "Windows/openings" button and a new page will appear. Here click the green boxed button "Edit List" and insert the windows as seen in the picture.

Be aware that the coordinate system of the chosen wall starts in the bottom left and the X’ – axis is the orientation of the window in horizontal direction and the Y’ – axis in vertical direction.

There is also a movie about this topic.

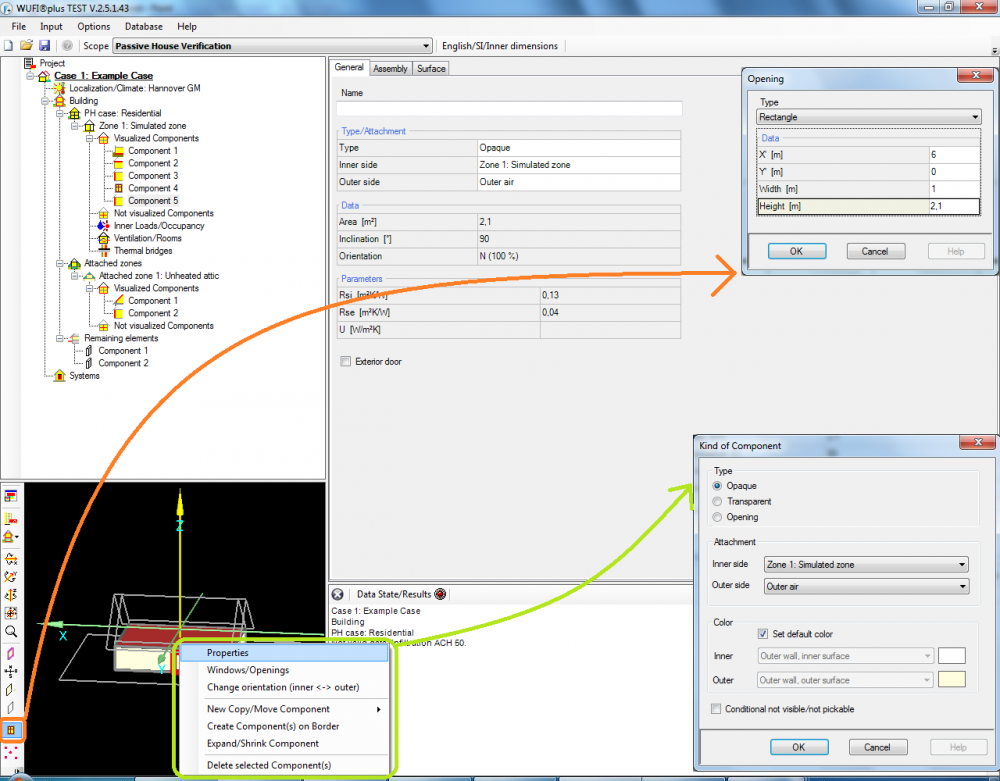

The door in the north orientet wall can be implemented almost the same way. Turn the building in the visualization box, create a "window" just like before and afterwards right click the new element and change its properties to opaque.

To clarify this is an exterior door, click on "Component 5" in the tree (if you are looking at the door in the visualization box, it will be red edged) and make a check on the "exterior door" option.

Step Three: Options for the passive house

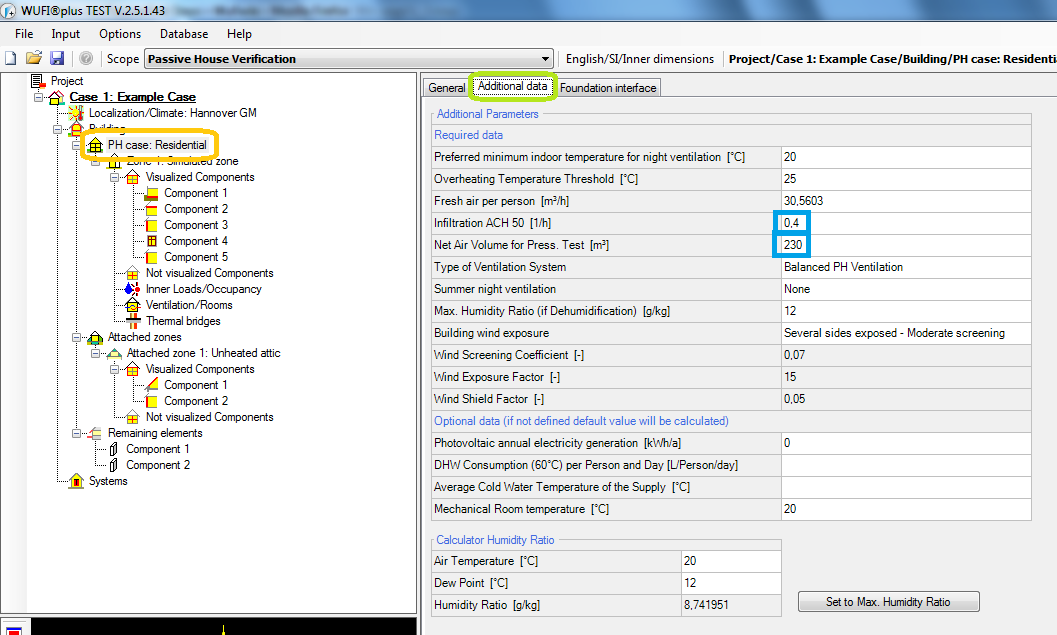

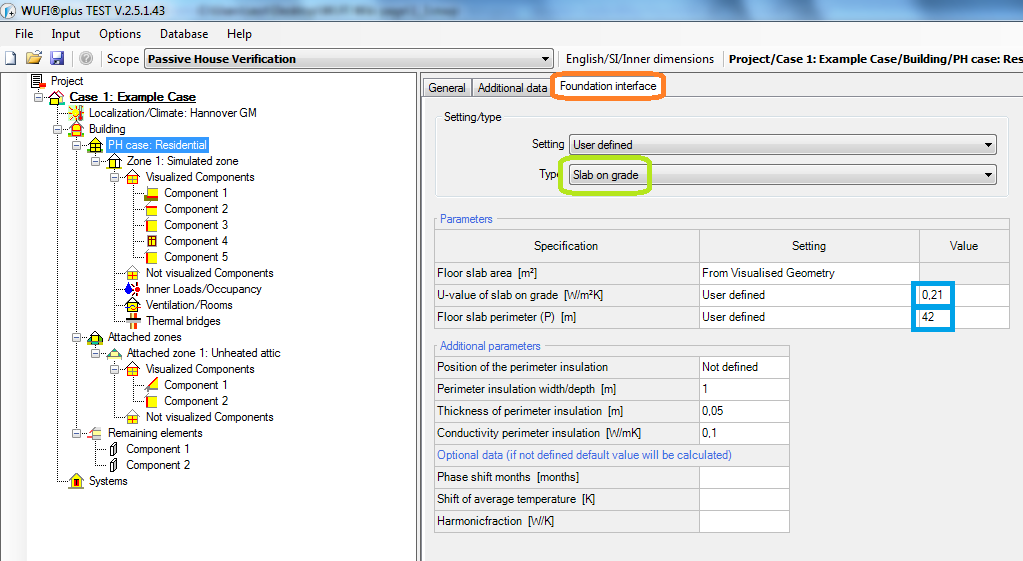

Next click on the "PH case:" section on the tree. Per default its value is "residential" and we will not change something in the "general" tab here. Instead we will go to "Additional data" and input the values being boxed blue in the picture.

Other than that we will not change any standart values but instead are going to the next section: "Foundation interface". There we will also just add some additional values.

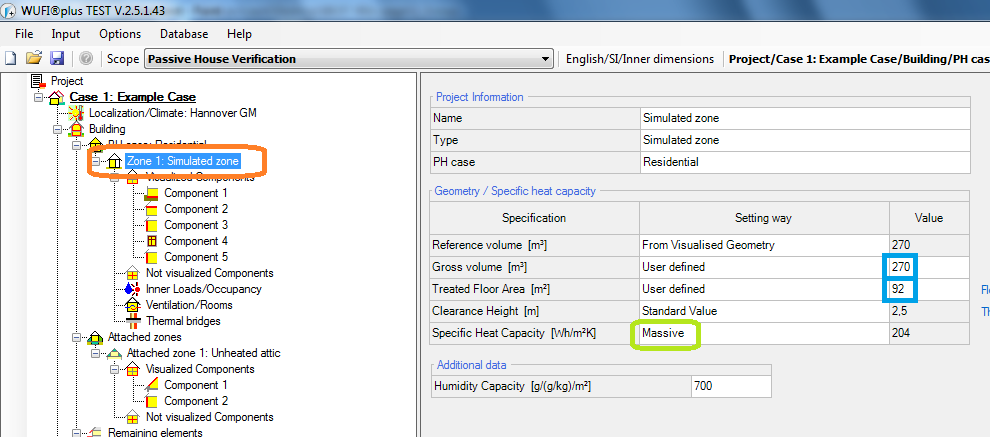

Step Four: Zonal data

In this section we will define the tfa and the gross volume of our building. In the green box we define the properties of our wall, in this case our wall is massive.

Step Five: Defining the components

The next subsection is all about the components and their assemblies. First we click on "Visualized components" and name each component.

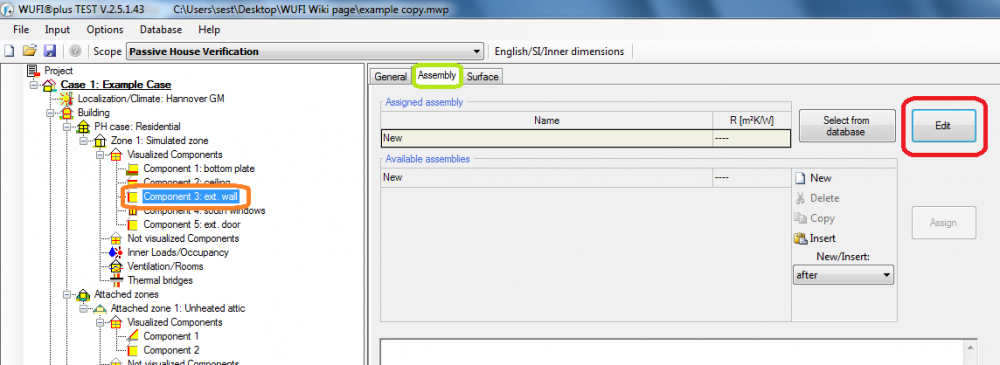

Then we define the assemblies of all components and we will start with the exterior wall as described in this movie.

Therefor we click on "Component 3:ext. wall" and then on the subsection "assembly" and then on the red circled "Edit" button.

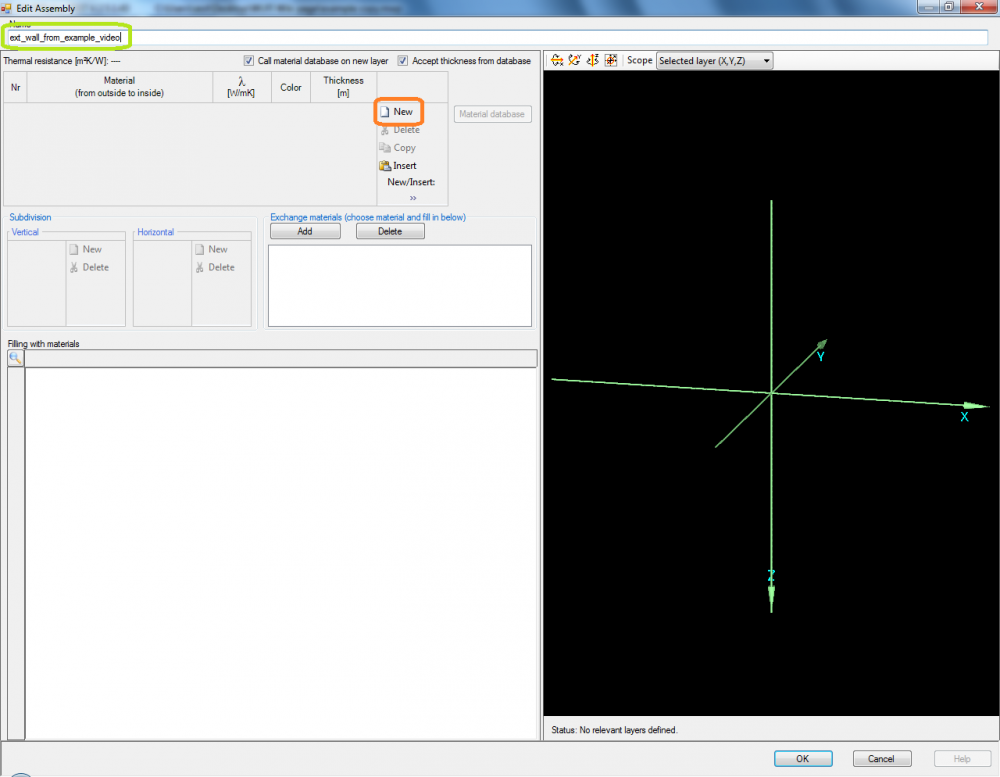

A new window will pop-up, where you can define the assembly. As seen in the video, we will construct a rear wall with wooden beams in it.

First we will name our assembly and then search for our needed materials by clicking on "New".

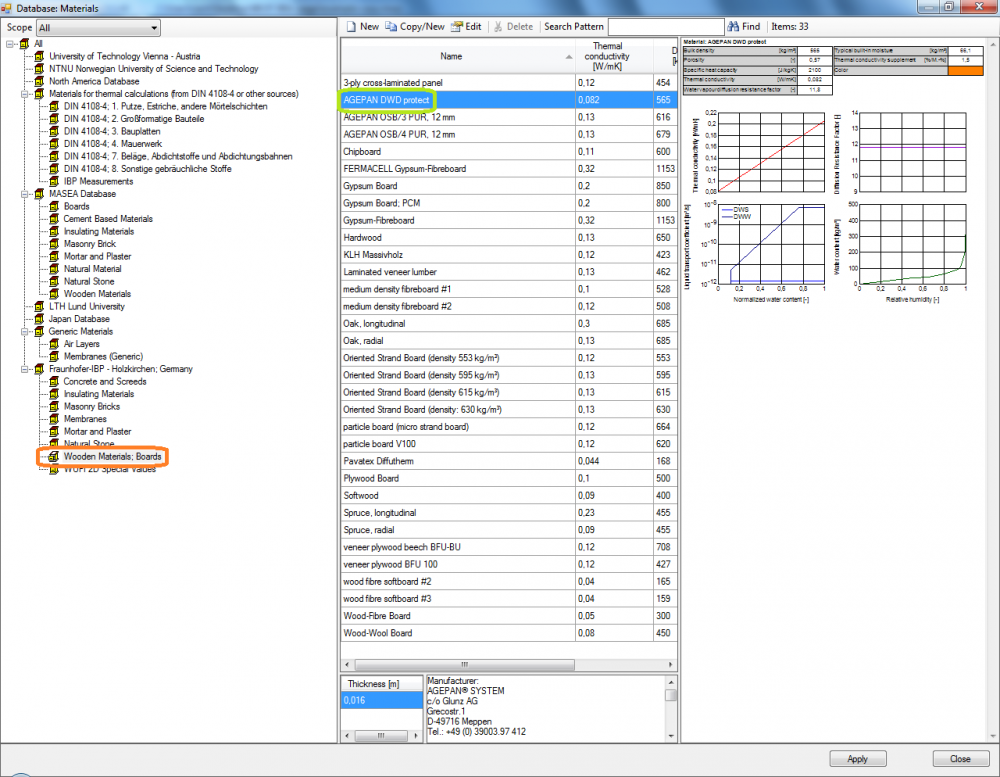

In the material database we will chose the "Wooden materials;Boards" section and define the first layer of our wall.

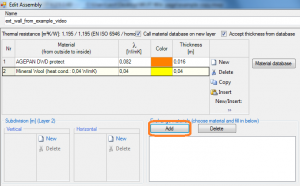

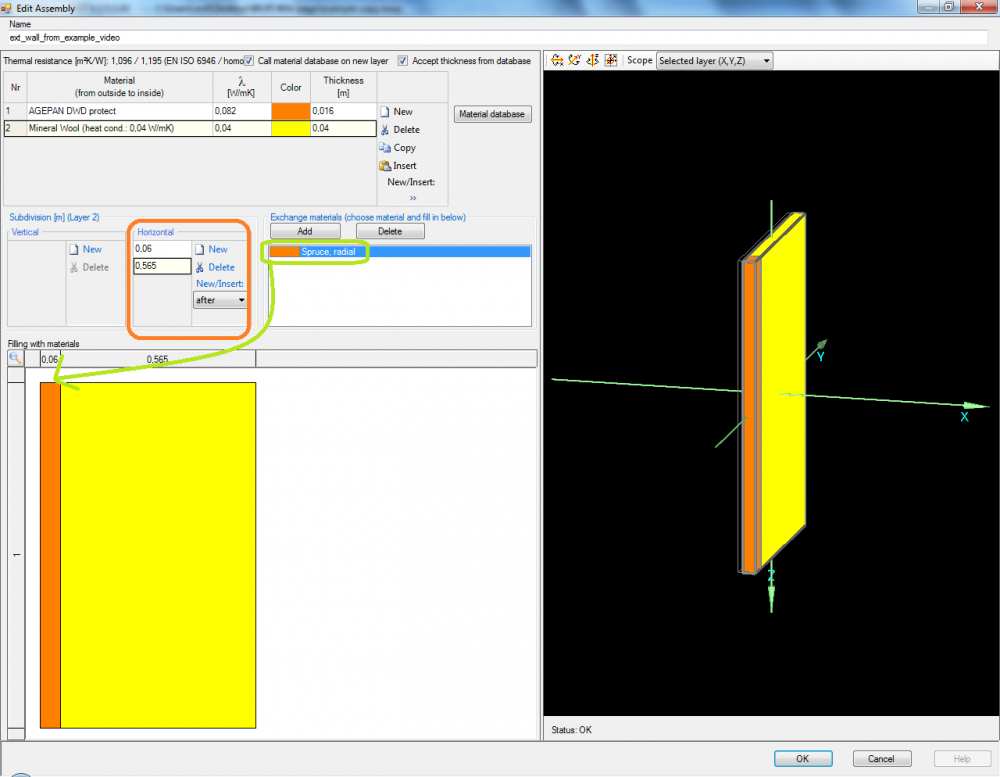

The next layer then will be an insulation material. In this layer are the interupting beams, so click on the "Add" button and you will get to the material database again. Select your beam material (in this case it is "Spruce, radial", which you can find in the "Wooden materials;Boards" section) and then the raster of the timber beams by creating new sections in the horizontal section. Then click on the spruce in the "exchange materials" box and click on the respective section as seen in the picture below.

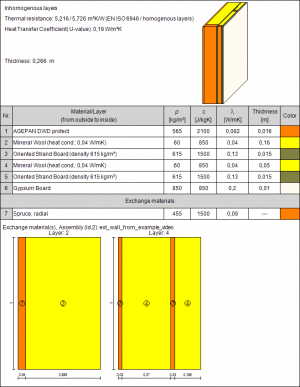

Define then the remaining layers so that the assembly consists of following materials:

| Material | λ | Thickness |

| AGEPAN DWD protect | 0,082 | 0,016 |

| Mineral Wool (heat cond.: 0,04 W/mK) | 0,04 | 0,05 |

| Oriented Strand Board (density 615 kg/m³) | 0,13 | 0,015 m |

| Mineral Wool (heat cond.: 0,04 W/mK) | 0,04 | 0,05 |

| Oriented Strand Board (density 615 kg/m³) | 0,13 | 0,015 m |

| Gypsum Board | 0,2 | 0,01 |

In the second layer of mineral wool more wooden beams are inserted. This time add three horizontal divisions with the dimensions 0,03 , 0,37 and 0,03. Fill in the spruce in both small gaps.

Back in the WUFI window, you have to assign the assembly to the respective component. The assign button is right beneath the edit button we used before.

You can also use predefined or save your own assemblies here or by clicking the "Select from database" button right next to the "Edit" button we used earlier. This comes in handy, if you want to use the same assembly at different projects.

Now it is time to define the other components as well;

| Ceiling | Bottom Plate | Exterior Door | |||||||||

| Material | λ | Thickness | Material | λ | Thickness | Material | λ | Thickness | |||

| Mineral Wool (heat cond.: 0,04 W/mK) | 0,04 | 0,3 | PVC Roof Membrane | 0,16 | 0,001 | EPS (heat cond.: 0.04 W/mK - density: 30kg/m³) | 0,04 | 0,05 | |||

| Concrete, w/c=0.5 | 1,6 | 0,1 | EPS (heat cond.: 0.04 W/mK - density: 30kg/m³) | 0,04 | 0,25 | ||||||

| Concrete, w/c=0.5 | 1,6 | 0,2 |

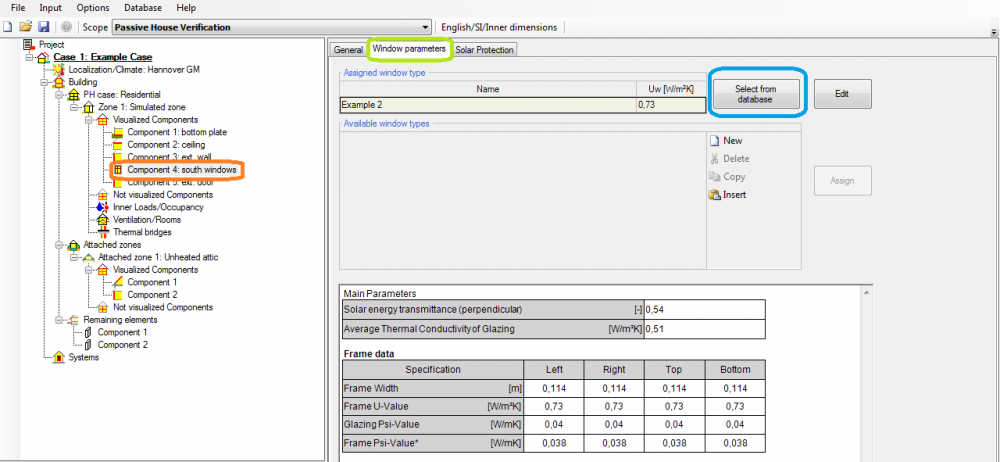

Windows

For this example, a predefined window is used. More about implementing windows and their settings can be seen in this video.

The example 2 windows are predefined windows from the WUFI®Passive database and easy to find.

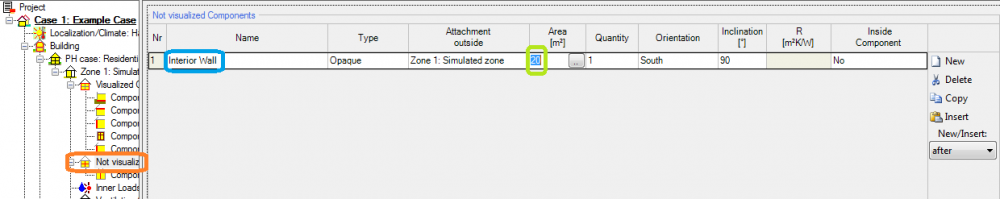

Step Six: Interior Walls

In this simple building, there is only one interior wall. Click on the "Not visualized components" part of the tree and input the data as seen in the picture below.

For advanced users: It is also possible to change its orientation and inclination as well as the attached zones. If doing the later, this component has to be defined the same way as the visualized components.

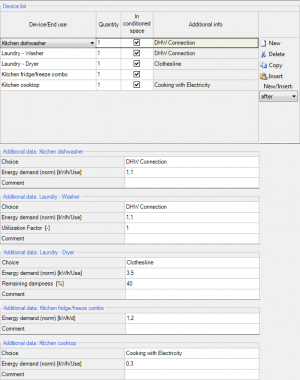

Step Seven: Inner Loads

The next step is the implementation of inner loads. Therefor click on the "Inner Loads/Occupancy" section in the tree and add the following appliances with its data into the list:

| Appliance | Quantity | Energy demand[kWh/use] or [kWh/day] | Additional Info |

| Kitchen - dishwasher | 1 | 1,1 | DHW connnetion |

| Kitchen - fridge/freeze combo | 1 | 1,2 | - |

| Kitchen - cooktop | 1 | 0,3 | Cooking with electricity |

| Laundry - Washer | 1 | 1,1 | DHW connection |

| Laundry - Dryer | 1 | 3,5 | Remaining Dampness: 40 / Clothesline |

WUFI also has a standart dataset with different settings as well as the possibility to input completely different appliances with a "user defined" option.

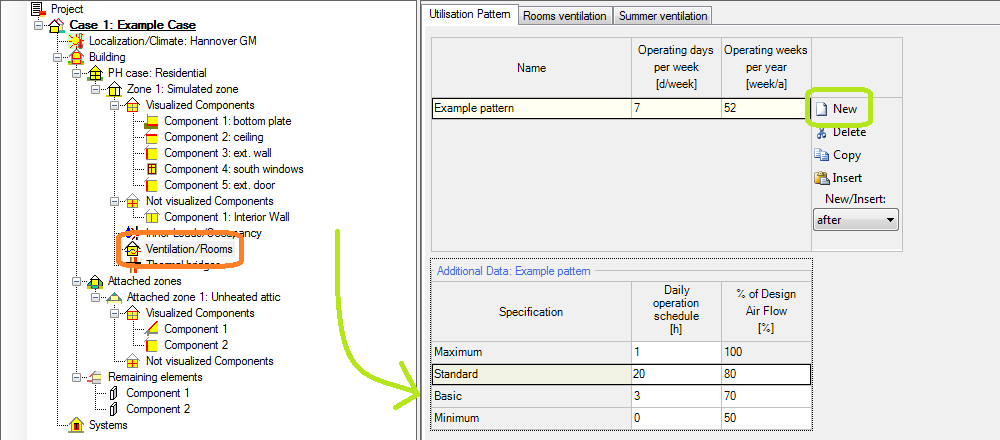

Step Eight: Implementing the ventilation

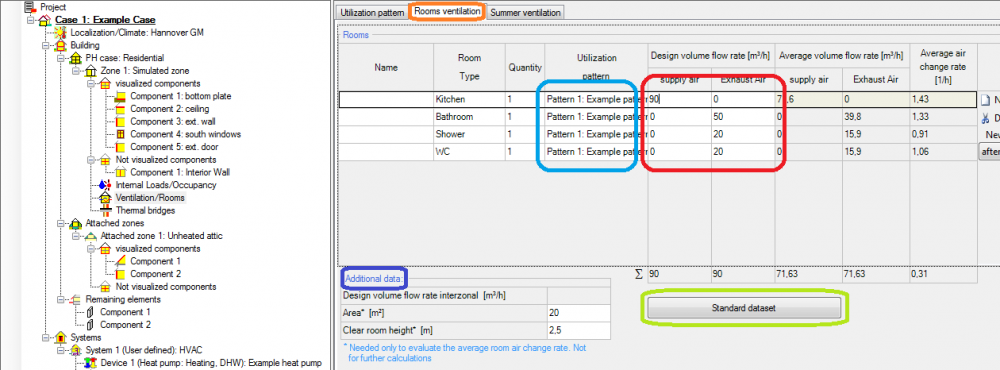

In this section each room can be occupied with different ventilation settings by defining different utilization patterns. In this case only one pattern will be defined and then used on every room. Click on the "New" button and then input the ventilation pattern as seen on the picture.

To apply this pattern to each room, click on the "Rooms ventilation" tab and then add four rooms, each one kitchen, bathroom, shower and WC by first clicking on the "Standart dataset" button (boxed green) or by pressing the "New" button on the right and then by chosing the respective scope in the "Room type" section. Then chose the desired pattern for each room in the "Utilization pattern" section of the table, in this case "Pattern 1: Example pattern".

Each room has a predefined value of exhaust air of the design volume flow rate, which you are free to change if necessary, but for this case use the predefined ones and set the same values on the supply air, as seen in the red box.

Each room has its own "Additional data" section where the area of the room and its clear room height must be added. For this example, use the values as seen in the table below:

| Kitchen | Bathroom | Shower | WC | |

| Area [m²] | 20 | 12 | 7 | 6 |

| Clear room height[m] | 2,5 | 2,5 | 2,5 | 2,5 |

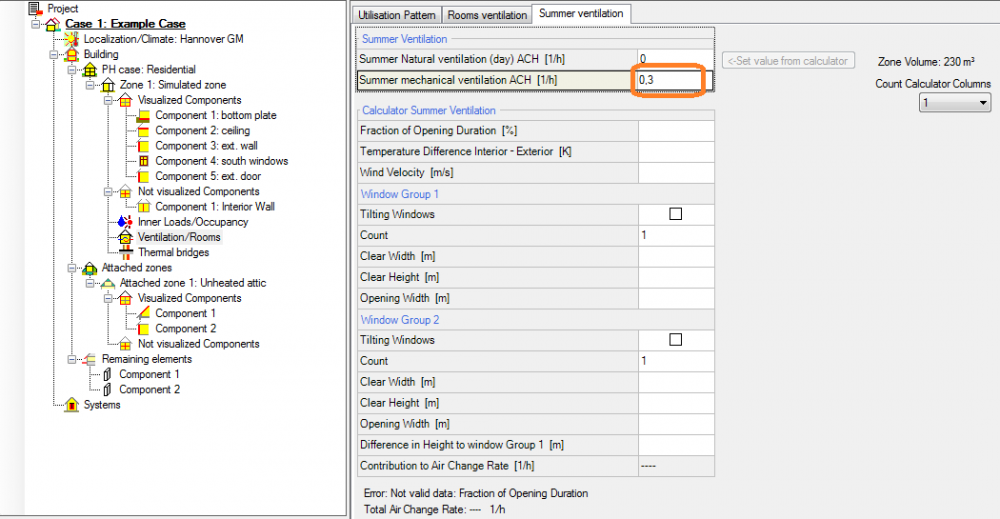

The last step regarding ventilation will be to add additional mechanical ventilation furing summer. Therefor click on the "Summer ventilation" tab and input a 0,3 ACH as seen in the picture.

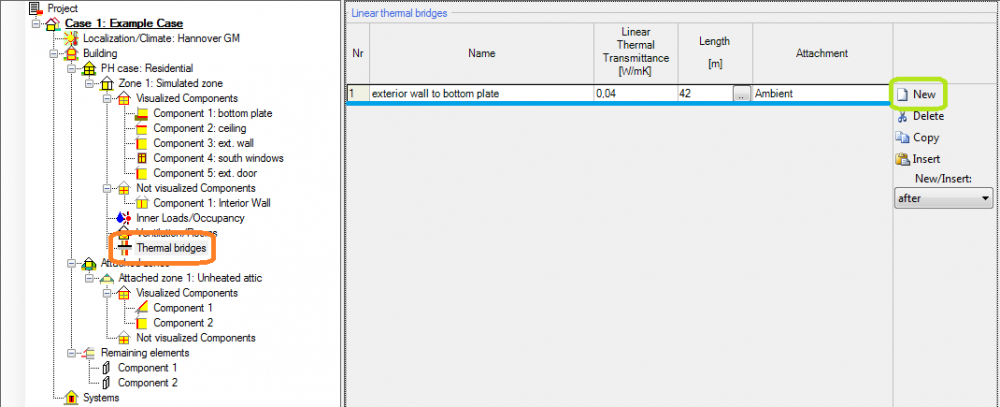

Step Nine: Thermal Bridges

Thermal brigdes have an underestimated influence on energy performance and are found in every building. In our example building there is only one so add it by clicking on the "Thermal bridges" section in the tree and then on the "New" button on the right side. The thermal bridge has a linear thermal transmittance of 0,04 W/mK and is 42 meters long.

Step Ten: Intermezzo with the unheated attic

For simplicity of this example, the attic is unheated and unventilated but does have a temperature difference reduction factor of 75%.